Series 700F Power Processor

(10kVA - 150kVA)

Description:

The Series 700F is a front access, tap switching, power conditioning voltage regulator which features a small footprint, high efficiency design, triple-shielded isolation transformer, tight output voltage regulation to ± 3%, and optional power quality monitoring. Digital processing provides fast, accurate regulation within one cycle, without over- or under-shoot. With a unique front access cabinet design, left, right, and rear access are not required for system installation, operation or service.

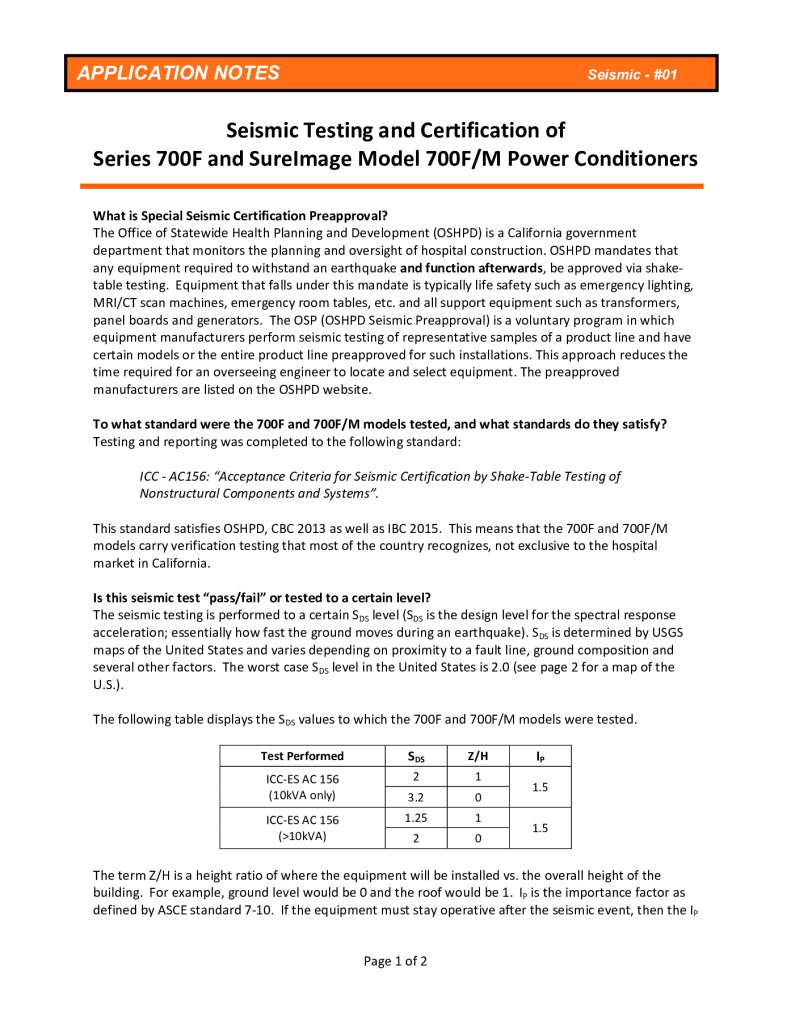

The Series 700F has been shake-table tested and each of our models are offered with an optional seismic rating. Seismic-rated Series 700F models are available with an input nominal voltage of 208VAC, 240VAC, or 480VAC and are provided on floor-mounting channels. These models meet seismic standards which satisfy the California Office of Statewide Health Planning (OSHPD) requirements, as well as CBC 2013 and IBC 2015 standards! The verification testing required is recognized and accepted by most of the U.S., as well as other countries, and not exclusive to the hospital market.

Learn more about our OSHPD Seismic Preapproval and test results!

Three Phase Sizes: 10kVA, 15kVA, 25kVA, 30kVA, 50kVA, 75kVA, 100kVA, 125kVA, 150kVA

- Front access only! All installation, operation, maintenance, and testing can occur from the front of the unit — no side or rear access required

- 7-tap, microprocessor-controlled for tight voltage regulation, accuracy, and stability.

- Precisely maintains correct voltage to ± 3% within 1 cycle, and maintains regulation during extended brownouts

- Extended input regulation range options including +10%, -40%; +15%, -25%; and +20%, -30%

- Low output impedance transformer minimizes voltage distortion and sags commonly associated with high surge currents

- Triple-shielded isolation transformer provides a noise-free ground, attenuates voltage spikes and transients, and re-establishes the N-G bond

- Optional internal manual bypass option maintains system isolation, voltage transformation, and power conditioning

- Superior compatibility with dynamic loads

- Increased surge capability, without the need for automatic bypassing, provides full-time power conditioning

- High-efficiency design results in lower operating cost

- Up to two (2) output circuit breakers can be selected on models 10kVA – 50kVA, and up to four (4) on models 75kVA – 150kVA. Consult factory for available breaker ratings

- Optional input and/or output meter with power quality monitoring and remote network communications

- Input Operating Voltage Range: +10%, – 20% from nominal (Extended regulation range options available.)

- Input Frequency: 60 Hz, ± 3%

- Input Power Factor: > .99 PF with resistive load

- Reflected Harmonics: Triplen harmonics are not reflected to the utility under non-linear loads

- Output Line Voltage Regulation: ± 3% from nominal

- Response Time: < 1/2 cycle

- Correction Time: 1 cycle

- Load Regulation: 2.5% typical, no load to full load

- Overload Rating: 200% for 10 seconds; 1000% for 1 cycle

- Common Mode Noise Attenuation: 146dB

- Transverse Mode: 3 dB down at 1kHz; 40 dB down per decade to below 50 dB with a resistive load

- Transient Voltage Suppression: Meets ANSI C62.41 Category B-3

- Efficiency: 96% – 97% typical, model and load dependent

- UL 1012 Listed, C-UL Listed to CSA C22.2, No. 107.1-01

- Pharmaceuticals/Labs

- Government/Commercial Buildings

- Broadcast Communications

- Telecommunications

- Concert Halls/Theaters

- Wastewater Treatment Plants

- Refineries/Petrochemical

- Aerospace

- Printing Presses

- Industrial Lasers

- Pulp/Paper Mills

- Food Processing Plants

- UPS Bypass & Power Distribution

Learn more about this product! Read our brochures and other supporting documents!

- What is a tap switching power conditioner?

- Are all tap switching power conditioners the same?

- Where should the Series 700F tap switching technology be used?

- What power quality advantages does the Series 700F offer?

- How much overload can the Series 700F handle?

- How does the Series 700F protect the load from a utility loss of phase condition?

- Is the Series 700F as reliable as other technologies?

Controlled Power Company warrants the Series 700F Power Processor to be free from defects in material and workmanship for a period of one (1) year following shipment from the factory. Controlled Power Company agrees to replace, F.O.B. its factory, any parts which fault through defect in material or workmanship during the warranty period.

Warranty begins from date of shipment unless a factory start-up is purchased, then the warranty begins from date of start-up or 90 days from ship date; whichever comes first.

Consult the factory for additional warranty details, and a description of start-up services provided.